|

| March 10, 2020 | Volume 16 Issue 10 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

3D printing: Army works on cutting-edge munitions

The first of two Terminal High Altitude Area Defense interceptors is launched during a successful intercept test. Army researchers say additive manufacturing can improve the design and performance of Army munitions, including anti-ballistic missile defense systems to neutralize enemy capabilities. [Photo Credit: U.S. Army]

Advancements in additive manufacturing have fundamentally changed the scope of what we can design and build. Army researchers are exploring the technology through a program designed to push the technology to new boundaries.

Leaders at the U.S. Army Combat Capabilities Development Command's Army Research Laboratory at Aberdeen Proving Ground in Maryland recently designated several research programs as essential for future Army force modernization capabilities. As one of the initiatives, integration of additive manufacturing, also known as 3D printing, will play a vital role in Army-unique applications.

"Additive manufacturing has opened the door for the creation of geometric designs never thought possible with traditional manufacturing methods," said Dr. Jason Robinette, program manager of the laboratory's Science of Additive Manufacturing for Munitions, or SAMM Essential Research Program. "The goal of this program is to take advantage of recent advances in additive manufacturing for developing next-generation munitions."

This program directly supports two of the Army's modernization priorities: long-range precision fires and next-generation combat vehicles. According to Army officials, long-range precision fires aims to neutralize enemy capabilities, while next-generation combat vehicles pertains to land superiority in terms of firepower, speed, and survivability.

3D printers build parts in a layer-by-layer fashion and grant Army researchers precise control over the manufacturing process. Compared to the first-generation 3D printers, today's printers produce large builds in a relatively short amount of time and can incorporate high-performance polymers, composites, metals, and ceramics as feedstock materials.

According to Robinette, additive manufacturing has potential to improve the performance of munitions, electronic sensors, and fuzes through enhancements of specific production techniques.

Printed gun propellant charges and rocket motors could help achieve higher muzzle velocity and longer range, while better metal feedstocks may increase munition penetration to augment lethality. Researchers said additive manufacturing could even improve the efficiency and durability of electronic sensors and fuzes so they take up less space within the munition and better withstand extreme environments.

"We targeted specific components of the munition that we believe will be most impactful for the Army and has the best potential for transition," Robinette said.

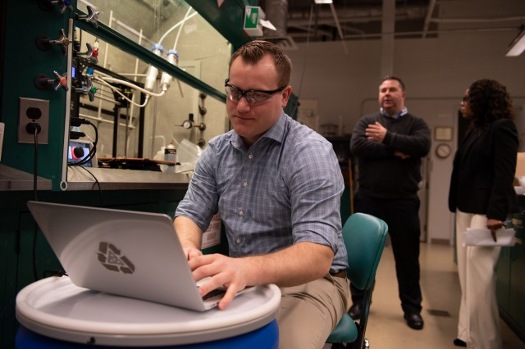

Army engineer David VanOosten (left) operates a polymer 3D printer inside one of the additive manufacturing laboratories at Aberdeen Proving Ground, MD. [Photo Credit: Neil Adams]

The research effort consists of three core teams specializing in energetics, metals, and hybrid additive manufacturing of munitions technologies, along with a design science team that brings together manufacturing and geometric design to uncover the underlying motive behind each project. In addition, the nature of the research inspires collaboration not just across different divisions and directorates in the laboratory's Weapons and Materials Research and Sensors and Electronic Devices Directorates, but also with teams in industry, academia, and other government agencies.

One of the major goals within this program is to address the issue of how 3D-printed items fail to retain the same mechanical properties as traditionally manufactured parts. Improvements to these features remain a top priority for the team to ensure that 3D-printed parts survive the rough conditions that future munitions will have to withstand.

"We have strategies in place to optimize feedstocks of metals, ceramics, composites, and polymers for improved adhesion and microstructure to address these concerns," Robinette said. "Once those problems are solved, we can start incorporating design tools in such a way to yield never-seen-before geometries for munition components that optimize performance."

In the short term, the research team plans to first demonstrate the viability of additive manufacturing processes on a component level within the munition. This effort would entail better combustion for propellants, more mass-efficient warheads, and optimized circuit designs on conformal surfaces. Further down the line, the program intends to demonstrate the integration of different 3D-printing technologies at a system level.

"For instance, we would want to know whether we can print metal casings to help mechanically support rocket motors for high-G survivability," Robinette said. "Can we start printing fuzing schemes to better integrate with explosive charges for increased lethality?"

So far, Army researchers have realized numerous accomplishments in additive manufacturing that promise more exciting developments in the future, Robinette said.

"We've printed the highest strength steel in the world in a more cost-effective way while maintaining its properties compared to its cast properties," Robinette said. "We've also printed the world's first 3D hybrid microcontroller circuit on a hemisphere that survived high-G environments comparable to what is experienced by today's munitions."

The team plans to obtain critical design specifications during testing and fine-tune the process to achieve greater performance. Throughout their efforts, the Army modernizations priorities remain at the forefront of their endeavors.

"I think the potential is endless," Robinette said. "But with this ERP, we're focused on nearer-term goals to try to deliver a product and capability for the Army that first feeds into its modernization priorities."

Source: U.S. Army CCDC Army Research Laboratory

Published March 2020

Rate this article

View our terms of use and privacy policy